|

|

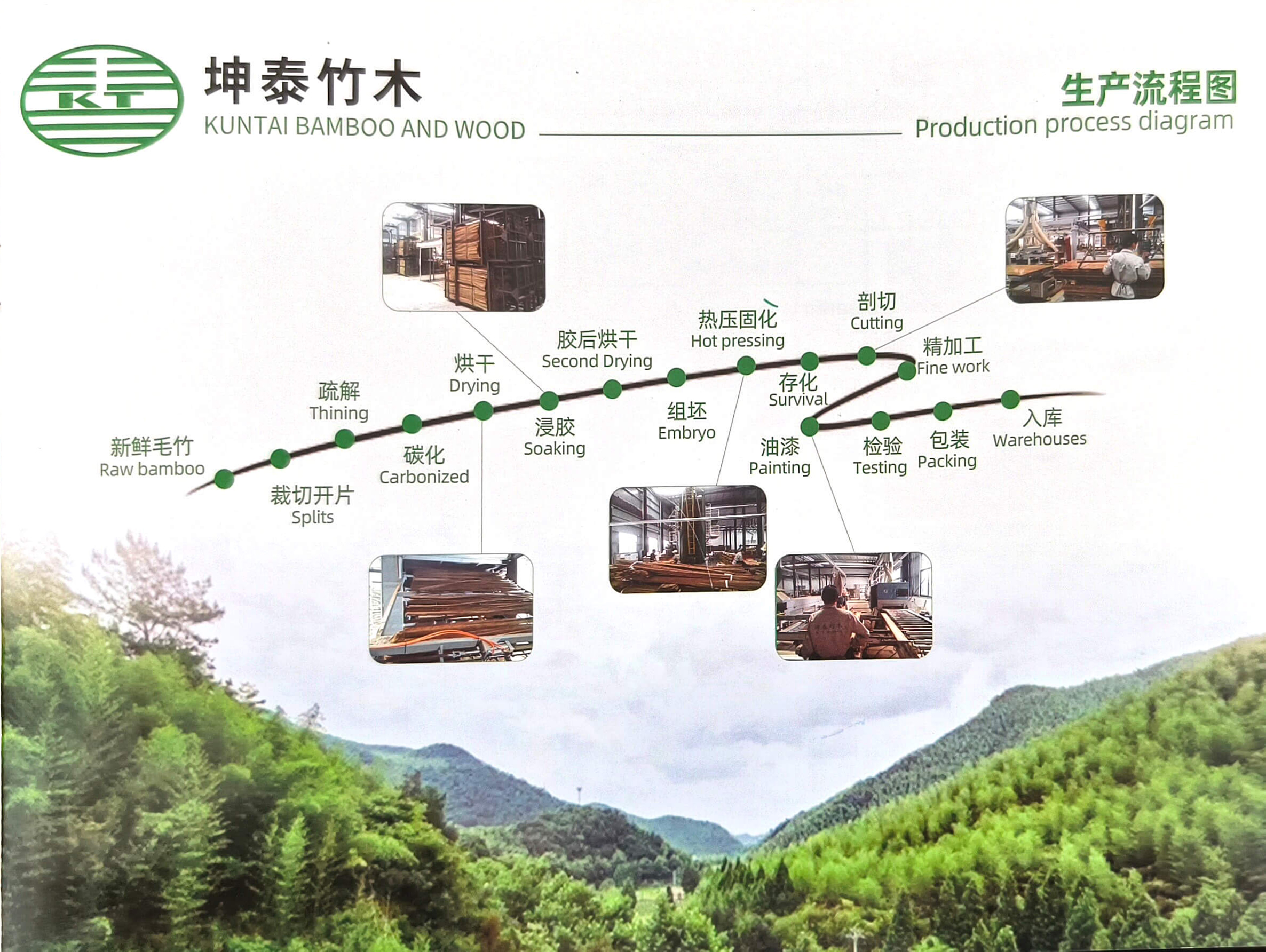

新鲜毛竹

Raw bamboo 选取六年及以上的优质毛竹 Select high-quality moso bamboo that are six years old or older |

|

|

裁切开片

Splits |

|

|

疏解

Thining 将竹材疏解成通长、相互交联并保持纤维原有排列方法的疏松网状纤维束 Decompose bamboo into loose network fiber bundles that are continuous, cross-linked and and maintain the original arrangement of fibers. |

|

|

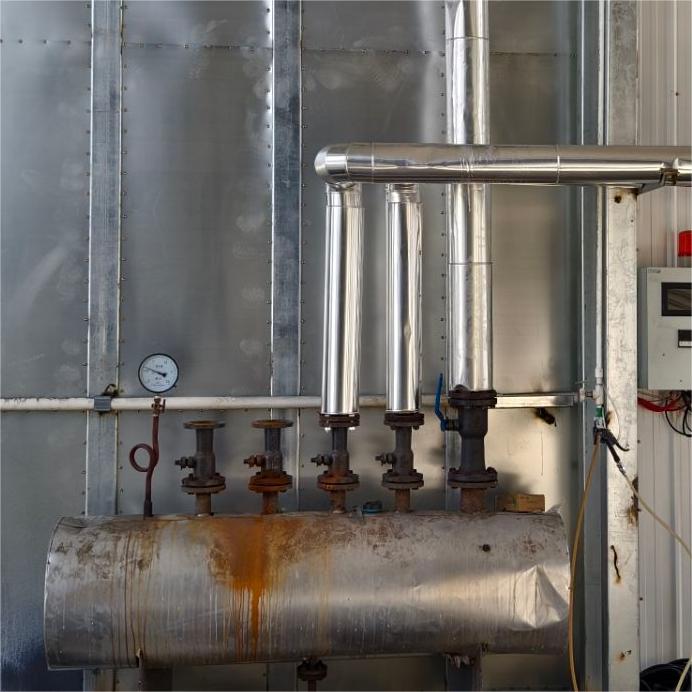

碳化

Carbonized 高温高压处理、防虫防霉效果显著、增强硬度和耐用性 High temperature and high pressure treatment, significant anti insect and anti mold effects, enhanced hardness and durability |

|

|

烘干

Drying 根据竹材的厚度和湿度进行调整烘干时间,将竹材的水分含量降低到适宜的水平,确保重竹地板在使用过程中不会因湿度变化而变形或开裂 Adjust the drying time according to the thickness and humidity of bamboo, reduce the moisture content of bamboo to an appropriate level, and ensure that heavy bamboo flooring will not deform or crack due to humidity changes during use |

|

|

浸胶

Soaking 使用自研胶水,控制用量,确保胶水能够牢固地粘合竹材 Use self-developed glue, control the amount, and ensure that the glue can firmly bond the bamboo |

|

|

热压固化

Hot pressing 施压加热固化一次完成,胚料成型过程是在几千吨的压力下固化完成,密度均匀,不易瘫边和跳丝,保证板胚的内在质量。 Pressure heating curing is completed in one go, and the process of forming the blank is completed under thousands of tons of pressure, with uniform density, less prone to edge collapse and wire jumping, ensuring the internal quality of the blank |

|

|

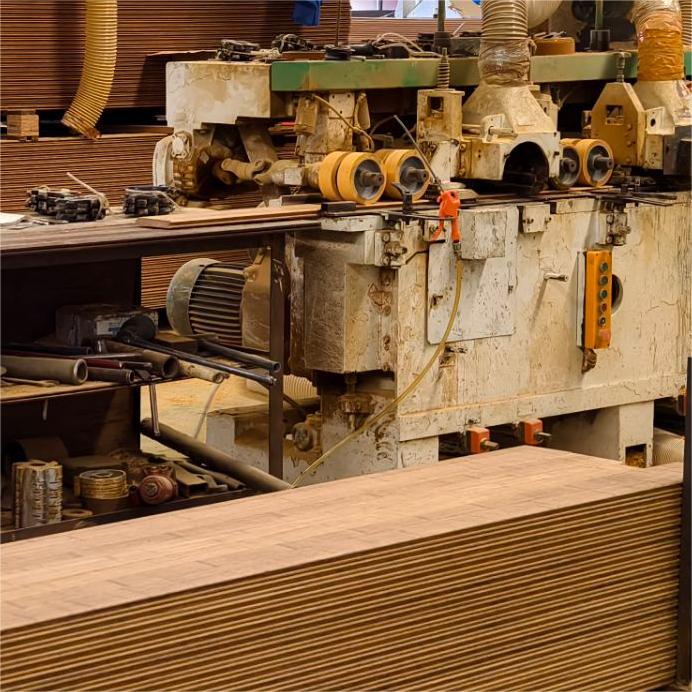

剖切

Cutting |

|

|

油漆

Painting 油漆过程中需要较长的固化时间,确保油漆层与地板基材的紧密结合,减少色差和表面不平整 A longer curing time is required during the painting process to ensure a tight bond between the paint layer and the floor substrate, reducing color difference and surface unevenness |

|

|

包装入库

Packaging and storage |